Beston company is a leading producer of waste recycling plants that has its headquarters located in China. The company has expanded significantly over the years to supply waste recycling machinery to several countries across the world, such as the United Kingdom, South Africa, South Korea, and the Philippines. On top of that, the company has grown massively to produce advanced eco-friendly machines that help control the menace of pollution and environmental degradation. There is an extensive list of Beston waste recycling plants in the market today, thanks to Beston Group. The article will address the critical determinants of the cost of tyre pyrolysis plant and the striking benefits that are associated with the recycling process.

Factors Determining Tyre Recycling Machine Price

There are no fixed prices for the tyre recycling plants because their costs vary depending on the following factors:

1. Cost of Spare Parts

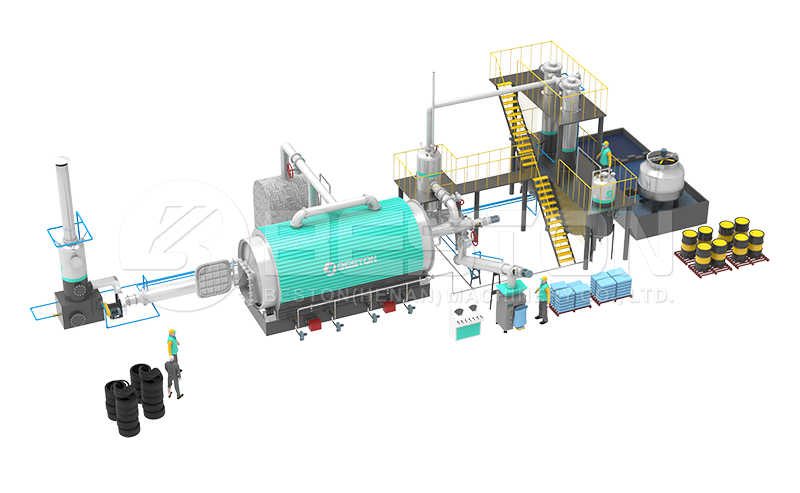

Tyre recycling plants are composed of the following components: oil gas cylinder, reactor chamber, dedusting systems, hydroseal, and the manifold. Beston Group has integrated all these components in the tyre recycling plant to achieve the end objective. The cost of these components has a direct impact on the overall cost of tyre pyrolysis plant. A piece of machinery that is composed of expensive spare parts will be more costly than that composed of cheaper spare parts.

2. Scale of Production

The scale of production of a plant also has a direct effect on the overall cost of the machinery. Beston has different models of waste tyre recycling plant for sale, which can process 6 to 24 tons of raw materials per day. The higher the daily production, the higher the cost of the recycling plant, and vice versa.

3. The Level of Technology Employed

The level at which advanced systems are integrated into the recycling machinery has a direct contribution to the cost of tyre recycling plant. Machines that are designed with more advanced sensors, emergency systems, and secure pressure valves cost more than those that are constructed with less technologically advanced equipment.

4. Control Systems Utilized

Tyre recycling plants that are fully automated cost more than those that are semi-automated. A fully automated tire recycling plant costs more because it eliminates human intervention during the recycling process. On the other hand, a semi-automated plant will cost less because it requires some human involvement to complete the recycling process.

5. Efficiency of Tyre Pyrolysis Plant

A tyre recycling machinery that can extract oil from rubber, tyres, plastics. The more the variety of materials that a plant can utilize, the higher the cost of that machine. Beston tyre recycling plant possesses a very high efficiency, which keeps it strides ahead of other competitors in the waste recycling industry.

Why Select the Beston Tyre Pyrolysis Plant?

Several outstanding reasons make the Beston machinery your best choice. These are:

1. Fully Automated Systems- Beston Group has designed advanced plants which have been verified by ISO. The automated system helps in reducing your production cost because it eliminates the number of operators you require to run the recycling facility.

2. Professional After-Sale Services- Besides designing efficient waste recycling systems, the Beston group offers professional after-sale services at subsidized prices. The services include maintenance and troubleshooting of the tyre pyrolysis plants.

3. Customizable Design- Beston waste recycling plant is designed with customizable features that enable you to alter the configurations of the machinery to meet your production needs. Additionally, qualified engineers from Beston Group are always ready to help you with the settings.

4. Environmental Friendly- The plant is designed with a four-layer dust removal mechanism that helps in the protection of the environment from pollution. Furthermore, the machine meets the safety standards of the EU Environmental Protection Body.

5. High Oil Output- The waste tyre recycling plant is designed with cutting-edge systems that produce maximum oil from rubber waste products. The high oil output makes the plant cost-efficient.

6. Presence of Explosion-Proof Systems- On top of the high oil outputs, Beston machinery is integrated with leading explosion-proof sensors and safety valves that protect the entire plant from fire accidents.

In a nutshell, understanding the factors that determine the pyrolysis plant price and the benefits that come with these machinery is essential. The knowledge is equally important when a country or parastatal is planning to commission a waste tyre pyrolysis plant from the Beston Group.