The waste tyre pyrolysis machine was delivered to Indonesia by the Beston Group and was put to use in 2017. The tyre pyrolysis machine is used to convert waste tyres into useful products such as fuel oil, carbon black, steel wires, and combustible gas. The pyrolysis machine has helped Indonesia recycle most of its tyre products effectively and efficiently. Besides Indonesia, Beston Company has exported the tyre pyrolysis plant to other countries across the world like England, Jordan, Turkey, and South Africa.

Essential Components of the Tyre Pyrolysis Machine

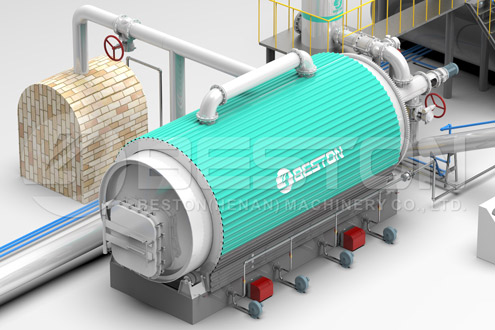

The tyre pyrolysis machine is composed of the following essential parts:

1. The De-Dusting System- The system is used to treat toxic emissions produced by the plant.

2. The Condenser- The condenser transforms gaseous oil into liquid oil.

3. The Manifold- The manifold separates the heavy oil from light oil.

4. The Casing Material- The casing prevents unnecessary heat losses from the pyrolysis reactor.

5. The Reactor- The reactor is the chamber where the breakdown process of the rubber takes place.

Special Technology Features to Improve Oil Yields

The Beston small pyrolysis plant (https://bestonmachinery.com/pyrolysis-plant/small/) has advanced technology features that help to boost the production of oil from waste tyres. The features are explained in details below.

– The plants have tubular condensers which increase their surface areas of cooling leading to higher oil yields.

– The reactor is fed with a catalyst that increases the pyrolysis rate and at the same time improve the quality of fuel oil produced.

– The tyre pyrolysis machine has incorporated the latest advanced systems that can sustain the pyrolysis process throughout depending on the needs of the customers.

Applications of the Pyrolysis Products In Indonesia

During the pyrolysis process, the following products are produced:

1. Carbon Black- It is mixed with clay to make construction bricks and can be reprocessed to produce pure carbon. The ICALTD facility in Indonesia has focused on the processing of carbon black into useful carbon products.

2. Fuel oil- Fuel oil is used as fuel for heating applications, making lubricants, and for powering vehicles. Chevron Pacific and ExxonMobil oil companies in Indonesia can also use the produced oil to boost their oil reserves.

3. Steel Wire- Steel wire can be sold directly in the Indonesian market and can be used to make new steel products in Krakatau Steel Company.

4. Combustible Gas- Combustible gas is recycled back to the reactor for heating purposes.

Working Principle of the Tyre Pyrolysis Plant

– The end objective of the tyre to oil pyrolysis plant is to produce oil, carbon black, and steel wires from waste tyres.

– The waste rubber materials are put in the pyrolysis reactor, and the reactor is sealed to prevent the entry of air in the system.

– The reactor is then heated to temperatures of approximately 280 degrees Celsius to break down the rubber molecules in the tyres.

– The oil gas rises to the gas separator where the heavy oil flows to the oil tanks and the light oil enter the condenser where it liquefies to form crude oil. The heavy oil flows back to the reactor for further refining.

– Carbon black and steel wires are recovered from the tires when they cool down. They are packaged and taken to the market for sale.

1. The plant has opened up so many employment opportunities in Jakarta, Bandung, and Surabaya among other Indonesian cities.

2. The waste tyre pyrolysis plant has improved the economy of Indonesia in a significant way by increasing trading activities in cities such as Jakarta.

3. The plant has improved the organization of Indonesian towns because the numbers of tyres and plastics in damping sites has been reduced significantly.

4. The pyrolysis plant converts waste products into useful products such as oil which is an essential ingredient for improving the economy.

Environmental Advantages of the Pyrolysis Plant in Indonesia

1. Reduction of Greenhouse Gases Emission- The pyrolysis plant has helped in reducing emissions of sulphur dioxide and carbon dioxide from Industrialized towns such as Medan in North Sumatra. Accordingly, it is an environmental-friendly machine.

2. Reduction of Deforestation Activities- Wood and other combustible materials recovered from wastes have been used for heating purposes and this has helped reduce the number of trees cut in Borneo lowland rainforest in Indonesia.

3. Improvement of the Beauty of the Landscape- The tyre recycling plant has made Jakarta, the capital of Indonesia more beautiful than before.

4. Reduction of Pressure on Energy Sources- A lot of energy is required to convert raw materials into finished products. Recycling activities make the whole manufacturing process easier and this helps to reduce pressure on power generating companies such as Perusahaan Gas Negara and other sources of energy such as solar power.

The benefits that the waste tyre pyrolysis plant in Indonesia has brought to the Indonesian economy cannot be overlooked. From reducing environmental pollution to creating employment opportunities, and improving the economy, the pyrolysis plant has proven to be a project worth investing in. Here is the manufacturer for your reference: Beston (Henan) Machinery Co. ltd..