The growing demand for decarbonization across industries has positioned biochar production as a pivotal mechanism for carbon sequestration. Unlike traditional charcoal, which serves primarily as a combustion fuel, biochar functions as a long-term carbon storage medium with measurable climate benefits. The technological evolution driven by advanced pyrolysis systems and specialized engineering from each biochar machine manufacturer has created a tangible link between charcoal production and carbon credit generation.

Carbon Stabilization through Pyrolysis

At the core of this relationship lies the process of pyrolysis—the thermochemical decomposition of biomass under limited oxygen conditions. In controlled environments, biochar pyrolysis equipment converts organic matter such as wood residues, crop husks, or coconut shells into a stable form of carbon. This conversion immobilizes carbon atoms that would otherwise return to the atmosphere through natural decay or combustion. Each ton of biochar produced effectively locks away a corresponding volume of CO₂ equivalent, forming the scientific basis for carbon credit certification under international standards like Puro.earth or Verra.

The permanence of biochar’s carbon matrix differentiates it from short-term offset measures. With a molecular structure resistant to microbial degradation, biochar remains in soil for centuries, acting as a carbon sink while enhancing soil fertility and water retention. These dual environmental and agricultural benefits amplify its value within both carbon markets and regenerative land management systems.

Technology and Measurement Integrity

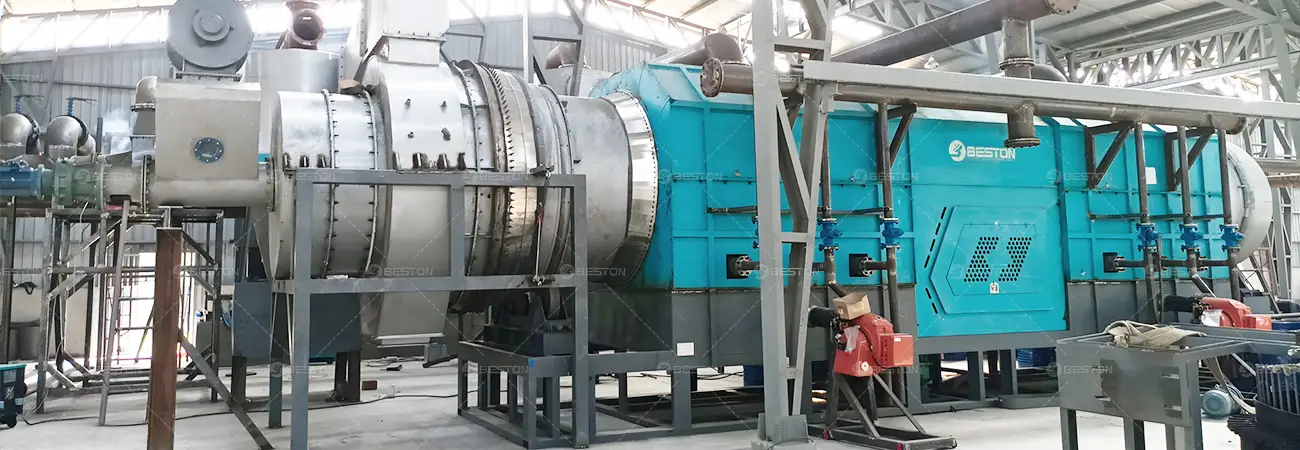

Modern biochar production relies on precise engineering to ensure consistent quality and verifiable emission reductions. Advanced systems integrate real-time temperature monitoring, gas recycling units, and emission filtration to achieve near-zero pollution. A leading biochar machine manufacturer typically designs reactors that operate within optimized thermal ranges—between 450°C and 600°C—to maximize carbon yield and minimize volatile emissions.

Biochar pyrolysis equipment is also designed to capture process gases such as syngas and bio-oil, which can be reused to power the reactor itself. This closed-loop energy balance enhances overall system efficiency while reducing dependence on external fuel sources. Such measurable process efficiencies strengthen the credibility of carbon accounting and support transparent verification in carbon credit programs.

Economic Dynamics and Capital Considerations

The financial feasibility of biochar projects depends heavily on technological scale and regional infrastructure. Biomass pyrolysis plant cost varies according to production capacity, automation level, and feedstock preparation requirements. Smaller installations may serve community-scale agriculture, while industrial units contribute to large-scale decarbonization portfolios. For developers, the upfront investment is often offset by the dual revenue streams from biochar sales and carbon credit issuance.

Furthermore, the use of modular components and standardized biochar kiln plans enables scalability and replication across multiple sites. This modularity supports distributed carbon capture networks—an approach increasingly favored in national climate strategies.

Linking Production to Climate Markets

The quantification of carbon retention is the linchpin connecting biochar production to financial incentives. Verified emission reductions are translated into tradeable carbon credits, providing tangible monetary value to climate-positive manufacturing. With transparent methodologies and third-party auditing, biochar producers can access voluntary carbon markets, attracting investment from corporations seeking credible offsets.

Through advanced pyrolysis engineering and rigorous measurement frameworks, biochar kiln plans has transcended its traditional role as a fuel-making process. It now stands as a scientifically validated pathway for carbon sequestration—an intersection of technology, economics, and climate action where innovation by each biochar machine manufacturer directly contributes to the global pursuit of net-zero emissions.