If you’re interested in a tyre pyrolysis plant, the leading manufacturers have got your covered. The best part of this is that they are continuous and they can effectively meet the demands of customers. The continuous pyrolysis plant can save the need for manual work. Read on as we dive into the continuous waste tire pyrolysis machine.

These pyrolysis plants were developed to deal with the rising issue of old ties, rubber, plastics, and forms of medical waste. They are so efficient that they can even handle oil sludge. Since the continuous variant can easily handle capacities of up to 24 tons per day, they are more suited for larger recycling factories or simply customers who work with larger piles of waste tires.

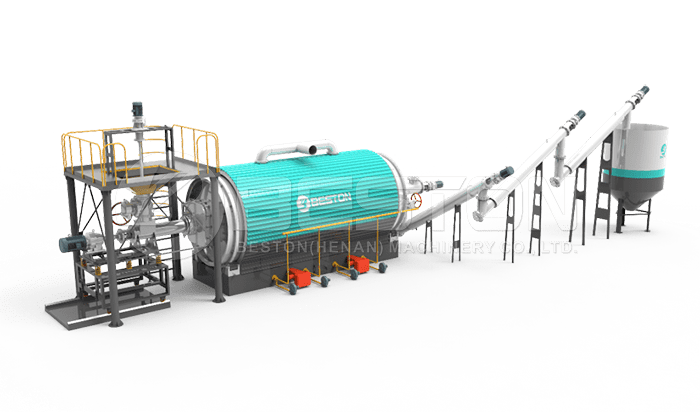

The continuous pyrolysis equipment is also equipped with an automatic feeder that makes the process easier. The tires are quickly fed into the reactor saving on the cost and manpower. These plants are also fashioned with a tire shredder. This ensures that the tires are in the appropriate sizes for processing; the efficiency is increased since the pieces are now smaller. If you have a batch pyrolysis plant to upgrade, you can check the link here to know more about the solution Beston offered to our clients.

Another advantage of the continuous waste tire pyrolysis plant is that it has the ability to continuously run for a complete 24 hour period. It can even discharge and feed materials all at the same time. So when compared to the semi-automatic or manual variant, they are more efficient and great at saving on the fuel cost with time.

The reactor employed in this version of the machine is stable and doesn’t rotate. Hence the temperature is known for rising faster and heating the oil tires faster. This also adds to the efficiency of the machine and contributes to saving fuel. The byproducts of this process can be used in different industries.

When tire oil is produced, it is then used in industrial processes as a form of fuel. If it undergoes further refining, it can be converted into gas or diesel and then used in low-speed engines. These include the road roller, digging machines, and loading machines. If you want to know how to start a pyrolysis plant, please check the link here: https://bestonasia.com/pyrolysis-plant.

Additionally, in an effort to reduce the energy crisis, the carbon black produced can be used as another source of fuel. It can also be mixed with clay to create blocks. Carbon black can also be further processed to create N220 and N330 Carbon black. They are known for having a wider application and a higher value on the markets.

The products can also be made into briquette for burning or even converted into materials for cable jacks and pipes. The steel wire removed from the tires can be reprocessed and used as iron rods or steel.

As we conclude, we have just looked at the waste tire recycling plant. These plants were created to relieve the issue of oil tires that are known for creating environmental hazards. The byproducts produced after processing can be used in several different industries and they have a wide array of advantages. Some of the products can also be reprocessed to create a new product that has greater value.