Soil contamination due to oil sludge is a significant environmental challenge that affects land productivity and poses serious health risks. The accumulation of oil sludge in soil often leads to the degradation of soil quality, making it unsuitable for agriculture or habitation. One promising solution to address this issue is thermal desorption, a process that utilizes heat to remove contaminants, such as oil and hydrocarbons, from soil.

In this article, we explore how thermal desorption works, its advantages, and its role in repairing soil contaminated by oil sludge. By the end of this guide, you’ll have a clear understanding of this technology’s potential in environmental remediation.

What is Thermal Desorption?

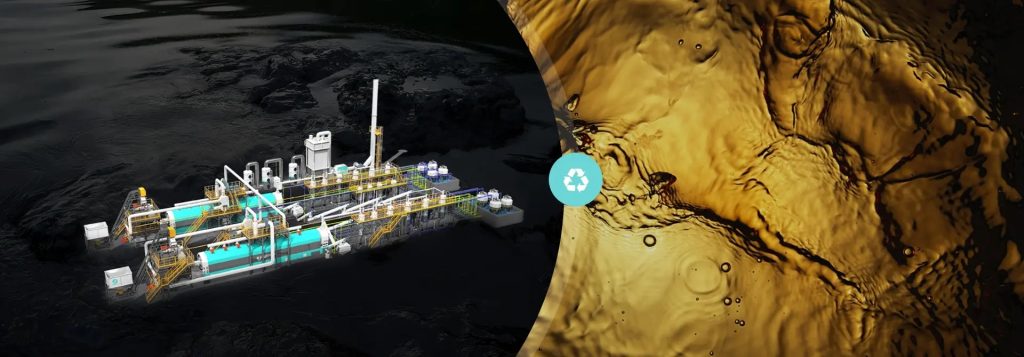

Thermal desorption system heats contaminated materials, such as soil, to temperatures that cause organic pollutants like oil, grease, and hydrocarbons to vaporize. Once these contaminants are vaporized, they are captured, condensed, and treated, leaving behind cleaner, safer soil. This process is widely used in environmental engineering to treat soils contaminated by petroleum products, heavy metals, and other toxic substances.

The process typically involves the following steps:

- Heating the contaminated soil in a desorption unit.

- Vaporizing the contaminants, which are then captured and condensed.

- Treating the extracted contaminants through various methods such as incineration or further refining.

The result is a significantly reduced concentration of pollutants in the soil, which can then be returned to its natural state or even be reused for agricultural purposes.

How Does Thermal Desorption Address Oil Sludge Contamination?

Oil sludge is a complex mixture of water, oil, and solid materials that can arise from various industrial processes, such as drilling, refining, or the handling of petroleum products. When it enters the soil, it can have detrimental effects on both the environment and human health. Traditional soil remediation techniques may not be as effective or cost-efficient for handling oil sludge contamination, but thermal desorption offers several benefits.

1. High Efficiency in Removing Oil-Based Contaminants

Thermal desorption oil sludge pyrolysis plant is particularly effective for the treatment of soil contaminated with oil sludge. The process can remove a wide range of petroleum hydrocarbons, including heavier oils and more stubborn residues, that may remain in soil after traditional methods have been applied. As it uses heat to break down the contaminants, the technique is able to target and vaporize even the most deeply embedded hydrocarbons.

2. Safe and Sustainable Solution

Thermal desorption is a relatively eco-friendly method compared to others, such as landfarming or incineration. Since the contaminants are vaporized and captured, there is minimal risk of secondary pollution or re-contamination. Moreover, the soil can be safely returned to the environment or reused, making it a sustainable remediation approach.

3. Cost-Effective for Large-Scale Projects

For large-scale contamination scenarios, such as oil spills or oil sludge dumps, thermal desorption pyrolysis machine can be more cost-effective than other treatment options. Unlike methods that rely on chemical additives or require lengthy recovery periods, thermal desorption can process large volumes of contaminated soil in a relatively short time. This makes it an attractive option for industries and government bodies dealing with significant contamination issues.

Benefits of Thermal Desorption for Soil Remediation

- Restoration of Soil Functionality: By removing harmful hydrocarbons and toxins from the soil, thermal desorption restores the soil’s ability to support plant life, thereby enhancing the land’s productivity.

- Reduction of Environmental Impact: This process minimizes the risk of long-term contamination of groundwater and surrounding ecosystems. By treating the pollutants efficiently, thermal desorption reduces the likelihood of environmental damage.

- Improved Health and Safety: Oil sludge contamination can pose serious health risks to humans and animals. Thermal desorption helps mitigate these risks by eliminating toxic compounds that can seep into water supplies or be absorbed into the food chain.

- Resource Recovery: In some cases, the process of vaporizing contaminants can also allow for the recovery of valuable byproducts like oil, which can be refined and reused, contributing to a circular economy approach.

Conclusion

Thermal desorption presents a promising and effective solution to address soil contaminated by oil sludge. By utilizing heat to remove harmful contaminants, this technology provides a safe, efficient, and sustainable method for soil remediation. As industries continue to face the challenge of managing contaminated lands, thermal desorption will likely play an increasingly important role in mitigating environmental damage and restoring soil health.

In summary, thermal desorption not only offers a high degree of efficiency in soil cleanup but also supports environmental sustainability by ensuring the soil is returned to a safer, productive state. As this technology continues to evolve, it holds great potential to address some of the most pressing environmental challenges posed by oil sludge contamination. More in Beston Group.