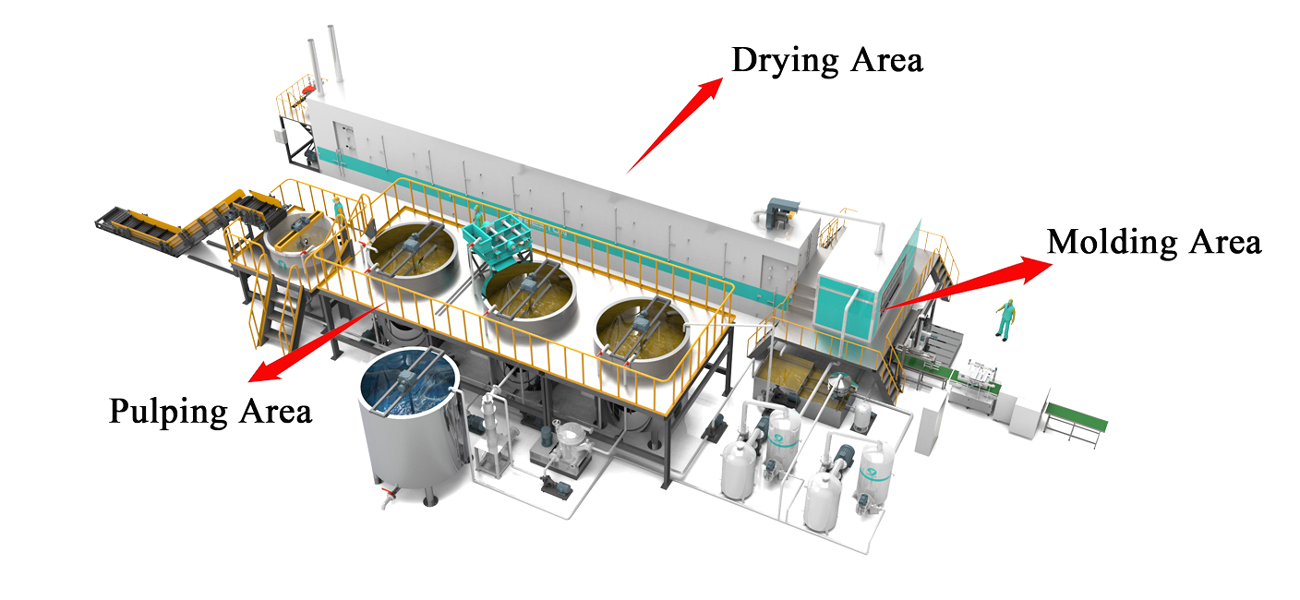

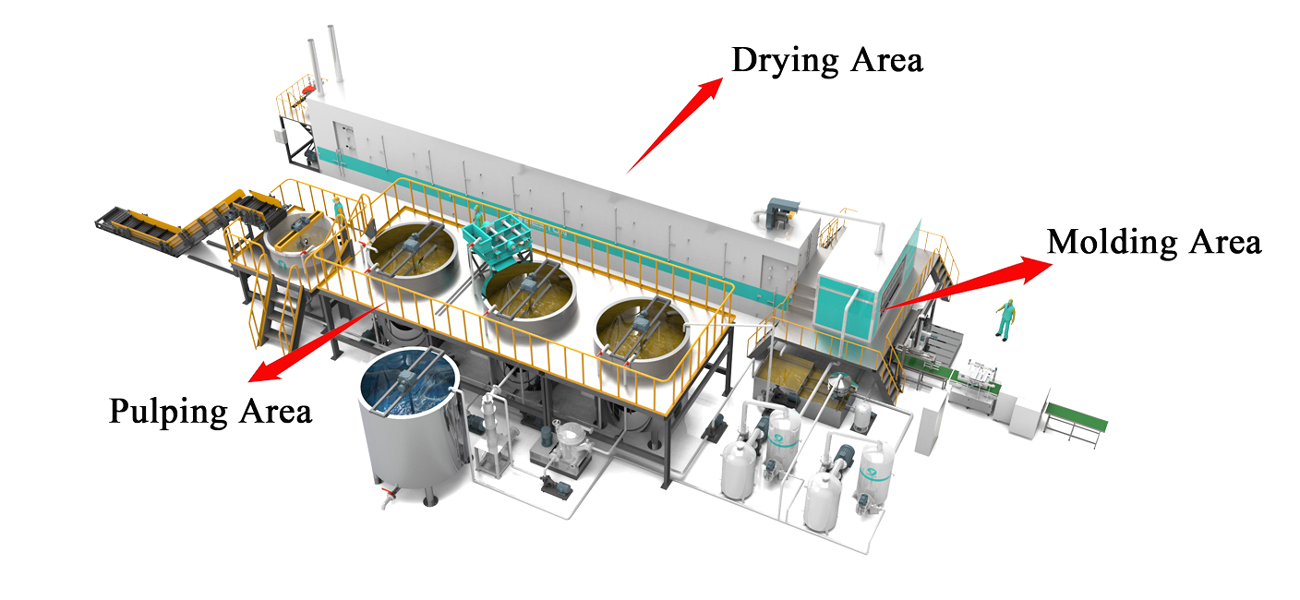

In the realm of sustainable production, the pulp moulding machine stands as a critical asset for converting waste paper into high-demand packaging products. Its operational versatility supports the fabrication of various items such as egg trays, fruit trays, shoe supports, and even medical containers. Selecting the right machine requires a nuanced understanding of production variables, capacity expectations, and budgetary constraints.

Evaluate Production Capacity

The primary consideration lies in matching machine capacity with actual production demand. A small-scale facility may only require a semi-automatic pulp egg tray making machine, capable of producing 1,000 to 2,000 units per hour. In contrast, a high-volume operation typically necessitates a fully automated system that incorporates a metal drying line and robotic stacking mechanisms. Overcapacity inflates operational costs, while undercapacity impedes profitability. Each manufacturer must calculate hourly throughput based on client orders, storage capabilities, and potential for expansion.

Examine Mould Configuration and Material Flexibility

The moulding segment defines the final product’s precision. Stainless steel moulds are standard for durability and corrosion resistance, but custom aluminum variants may be used for enhanced thermal conductivity and refined shaping. A high-quality pulp moulding machine should permit quick changeover of moulds, allowing seamless transition between different tray types without extended downtime. Compatibility with diverse paper pulp formulations—ranging from virgin pulp to highly fibrous recycled material—is equally vital, especially when raw material availability fluctuates.

Consider Energy Efficiency and Drying Options

Energy consumption is a major operational cost. Machines equipped with advanced thermal recycling systems and multi-layer drying tunnels deliver better energy efficiency over time. A buyer should compare drying methods—natural drying, brick drying, and metal drying lines—based on regional climate and required drying speeds. In humid or monsoon-prone zones, reliance on natural drying is unfeasible, reinforcing the need for mechanized drying integration within the pulp egg tray making machine.

Assess Control Systems and Automation Level

The evolution of pulp moulding machinery has introduced intelligent control systems, including programmable logic controllers (PLCs) and touch-screen human-machine interfaces (HMIs). These features support precise control over pulp distribution, vacuum forming, and demoulding cycles. For businesses targeting continuous output and minimal human intervention, investing in a high-automation unit provides both operational consistency and reduced labor dependency. Such systems often correlate with a higher industrial packaging machine price, yet yield stronger long-term ROI.

Factor in Equipment Durability and Maintenance

Long-term reliability is essential. Machines should be constructed with high-tensile steel frames and anticorrosive components. Accessibility for maintenance—especially to high-wear zones like vacuum pumps, hydraulic units, and transmission belts—greatly affects equipment uptime. Many egg tray making machine for sale options emphasize their production speed, but overlook serviceability, leading to higher lifetime maintenance costs.

Match Budget to Output Goals

Budgeting should align with the scale of operations. Entry-level machines offer an attractive industrial packaging machine price for startups but may lack advanced automation. Conversely, fully integrated lines carry a premium cost, justified only when the expected volume and revenue can offset the capital outlay. The key lies in striking equilibrium between upfront investment and projected output.

Conclusion

Selecting an appropriate pulp moulding machine is a multifaceted decision. It is driven not only by current demand but also by a strategic vision for operational scaling, material flexibility, and energy optimization. A well-chosen machine ensures consistent output, material efficiency, and sustainable packaging outcomes across market cycles.