Although it would seem to be a simple process, making egg trays from waste paper, it actually involves quite a bit of work and finesse. You can find manual, semi-automatic, and fully automatic egg tray machine for sale on the market. They are all set up in the same way, designed to receive different sizes of egg trays, depending upon the eggs that you are producing at any given time. Let’s discuss how the egg tray machines work, and why using a semiautomatic one might be the best value for your business.

It All Begins With Producing The Pulp

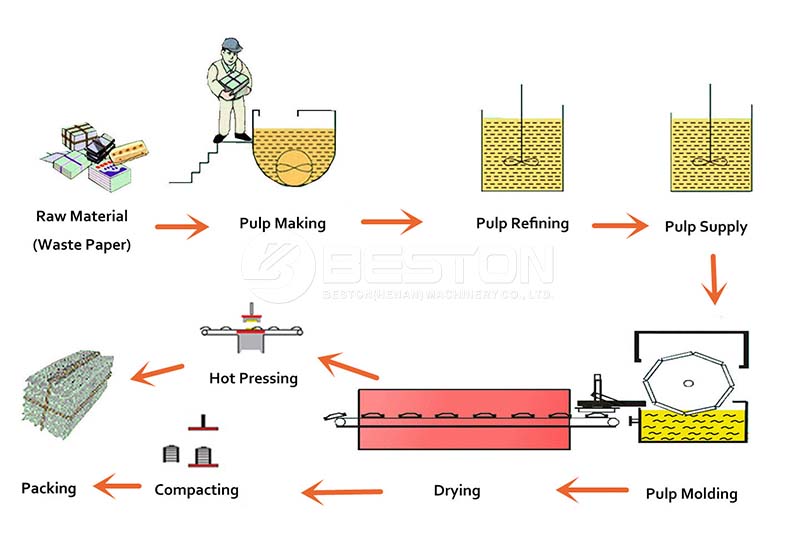

All of these machines will require some type of pulp that is traditionally made from recycled materials. There is a production line that all of these machines go through. The raw materials are weighed and broken down. They are then screened and cleaned, placed into a pulp tank, and then subsequently placed into a pulp forming machine. This is also called a pulp molding machine, one that has specifically sized trays, all of which are designed for the many different types of trays that can be produced daily. You can choose the different molding dies: https://bestoneggtraymachine.com/egg-tray-mold/.

What If It Is A Semiautomatic Machine?

This type of designation is somewhat of a misnomer because of the way that it is described. It seems to imply that not all of the processes are automated. In reality, it is only semiautomatic because of what happens once the egg trays have been made. With a fully automated machine, there is an elaborate conveyor belt system that is sometimes applied, allowing the trays to be distributed to different locations. Those that are not automatic will not have the systems. The stacking off of the trays, and the usage of the trays, is the part that does require manual labor.

Why Are These Less Expensive?

These are traditionally less expensive simply because the conveyor belt system can be extremely elaborate. Then the wet trays will be dried in the brick or metal egg tray dryer machine. It can cost thousands of extra dollars. However, if you can easily move the trays from the molding machine to where they need to be used for the eggs, then this should not be a problem for you at all. The businesses that tend to use fully automated units are producing millions of these cartons every year, and they already have workers that are functioning at different capacities all throughout the facility. It simply a great way to save money, yet also maintain your production levels for the production of egg cartons using these machines.

Semiautomatic egg tray machines are a very good investment. There are countries that produce thousands of them annually. From smaller ones to very large and elaborate units, you can look forward to producing thousands of egg trays on autopilot with many of them. It just depends on the manufacturer, the construction of the machine, and how well that they have designed it to be as efficient as possible. Your background research on different companies will need you to semiautomatic tray machine manufacturers that will provide you with the best units.