Have you ever considered what happens to your trash? Most people don’t give it much thought, but when you really think about it, there’s a lot of garbage we create on a daily basis. In the United States alone, over 250 million tons of trash is produced each year. This number is only going to increase as our population continues to grow. So, what can we do about all this waste?

One solution is to start using pyrolysis machine. Pyrolysis is the process of breaking down organic material into combustible gases and liquids through heat and pressure. These machines can turn even the most stubborn materials, like plastic and rubber, into fuel that can be used in engines or generators. Not only does pyrolysis help reduce waste, it also creates jobs in the recycling industry. If you’re interested in learning more about pyrolysis machines, keep reading. We’ll discuss everything from how they work to the benefits they provide.

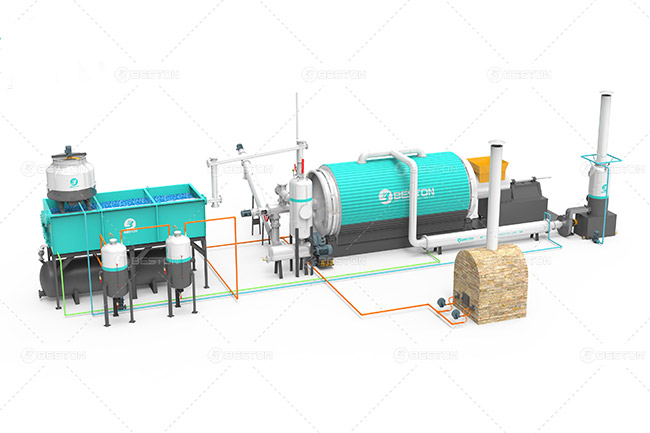

How Pyrolysis Machines Work

Pyrolysis is a process of thermal decomposition in the absence of oxygen. In a pyrolysis machine, feedstock material is placed in an oxygen-free chamber and heated to high temperatures. The high heat causes the feedstock to break down into its component parts, including gases, liquids, and char. The resulting products can then be used for a variety of purposes, such as fuel for power generation or as raw materials for manufacturing.

Pyrolysis is a versatile process that can be used to recycle a wide range of materials, from plastics to tires. And because it does not rely on oxygen, it can be used to process materials that would otherwise be difficult or impossible to recycle. As a result, waste tyre pyrolysis plant is an important tool in the fight against pollution and waste.

The Benefits of Using Pyrolysis Machines

It goes without saying that one of the biggest benefits of using pyrolysis machines is the reduction in waste. By recycling materials that would otherwise be destined for the landfill, pyrolysis machines help to reduce the strain on our environment.

In addition to reducing waste, pyrolysis machines also offer a number of other benefits. For example, they can be used to create new products and generate energy. Pyrolysis machines can also create jobs in the recycling industry, which is an important source of employment for many people. Get waste tyre pyrolysis plant cost here.

The Cost of Owning and Operating a Pyrolysis Machine

Pyrolysis machines are increasingly being used by industries to convert waste into energy. However, there is a cost associated with owning and operating these machines. The initial cost of purchasing a pyrolysis machine can be significant, and the ongoing costs of running the machine, such as maintenance and repairs, can also be high.

In addition, there is the cost of disposing of the waste material that is produced by the waste tyre to oil plant. This waste material must be stored and disposed of in an environmentally-safe manner, which can add to the overall cost of operating a pyrolysis machine.

Despite these costs, many businesses find that the benefits of using a pyrolysis machine, such as reduced landfill costs and increased energy production, outweigh the financial challenges. As a result, the use of pyrolysis machines is likely to continue to grow in popularity.