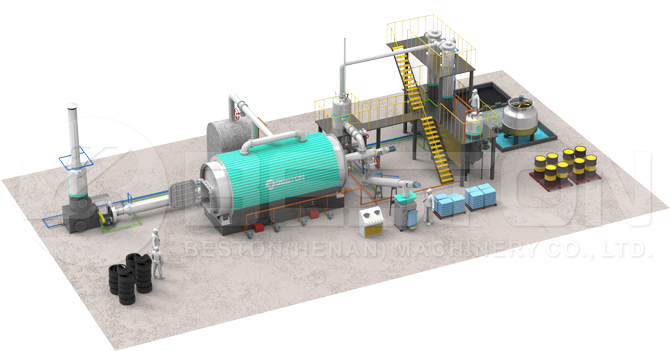

If you are looking to make some money from scrap tires, investing in a rubber pyrolysis plant from a reputable manufacturer would be a wise move. With such a plant, you can convert waste tires into tire oil. This tire oil can be easily refined with distillation equipment and sold in the global commodity markets for big profits. What’s more, tire pyrolysis plants are very affordable and are easy to source from worldwide manufacturers online. Keep reading to learn more waste rubber tire to oil machines for sale(оборудование для переработки шины в топливо).

Price

The price of a scrap tire pyrolysis plant largely depends on the size and automation level of the plant. Such plants are available in a wide range of sizes and you need to find one that meets the daily processing requirements of your tire recycling business as well as your budget. By choosing a plant with the right daily processing capacity that fits within your budget, your tire to oil business will be off to a good start.

Tire Oil Yields

Top-rated pyrolysis plants are rated that way generally because they have high oil yields. In other words, they employ technologies that ensure the maximum amount of oil possible is recovered from waste tires. The higher the oil yield, the larger your profits. A typically road tire, for example, is comprised of 50% tire oil. This means if you were to put 1 ton of tires in a 100% efficient rubber pyrolysis machine, 500 KG of fuel oil would be output. A less efficient pyrolysis plant would extract a smaller quantity of the total oil present in the raw scrap tires.

Pyrolysis Plant Running Costs

The running costs of a waste tire pyrolysis machine (установка пиролиза шин цена) are also something you need to take into account when producing a tire to oil plant business plan. The best pyrolysis plants have advanced heating reutilization designs. This means that any excess heat from the reactor is used to remove moisture from the raw materials prior to them being conveyed into the main reaction chamber. In addition, Beston’s pyrolysis plant channel all of the combustible gas produced during tire pyrolysis back to the reactor furnace to be used as reheating fuel, setting up a self-perpetuating operation and reducing plant energy running costs significantly.

Tire To Oil Machine Automation Levels

The automation level of a tire pyrolysis plant can have a big impact on the price. You can find batch/manual tire pyrolysis plants for sale, as well as semi-automatic tire to oil pyrolysis machines and fully continuous/automatic waste rubber pyrolysis plants. In general, the higher the automation level the higher the cost. That said, you have to take into account the fact that plants with higher degrees of automation will require fewer manual workers for operation. Therefore, labor costs should be an important factor in your cost analysis calculations.

Manufacturers

There are many global manufacturers in the pyrolysis plant industry. Beston is arguably one of the leading manufacturers in the field, but there are lots of other vendors also selling scrap tire pyrolysis reactors. So, the essentialness of buyer research can’t be overstated.